SWG to mm conversion chart

The current practice of the Institute of Electrical and Electronics Engineers (IEEE) is to reflect the American Wire Gauge in customary English units in parallel with metric units of measurement.

| SWG # | Diameter (mm) |

Diameter (inch) |

Area (mm2) |

| 4/0 | 10.160 | 0.4000 | 81.0732 |

| 3/0 | 9.449 | 0.3720 | 70.1202 |

| 2/0 | 8.839 | 0.3480 | 61.3643 |

| 0 | 8.230 | 0.3240 | 53.1921 |

| 1 | 7.620 | 0.3000 | 45.6037 |

| 2 | 7.010 | 0.2760 | 38.5989 |

| 3 | 6.401 | 0.2520 | 32.1780 |

| 4 | 5.893 | 0.2320 | 27.2730 |

| 5 | 5.385 | 0.2120 | 22.7735 |

| 6 | 4.877 | 0.1920 | 18.6793 |

| 7 | 4.470 | 0.1760 | 15.6958 |

| 8 | 4.064 | 0.1600 | 12.9717 |

| 9 | 3.658 | 0.1440 | 10.5071 |

| 10 | 3.251 | 0.1280 | 8.3019 |

| 11 | 2.946 | 0.1160 | 6.8183 |

| 12 | 2.642 | 0.1040 | 5.4805 |

| 13 | 2.337 | 0.0920 | 4.2888 |

| 14 | 2.032 | 0.0800 | 3.2429 |

| 15 | 1.829 | 0.0720 | 2.6268 |

| 16 | 1.626 | 0.0640 | 2.0755 |

| 17 | 1.422 | 0.0560 | 1.5890 |

| 18 | 1.219 | 0.0480 | 1.1675 |

| 19 | 1.016 | 0.0400 | 0.8107 |

| 20 | 0.914 | 0.0360 | 0.6567 |

| 21 | 0.813 | 0.0320 | 0.5189 |

| 22 | 0.711 | 0.0280 | 0.3973 |

| 23 | 0.610 | 0.0240 | 0.2919 |

| 24 | 0.559 | 0.0220 | 0.2452 |

| 25 | 0.5080 | 0.0200 | 0.2027 |

| 26 | 0.4572 | 0.0180 | 0.1642 |

| 27 | 0.4166 | 0.0164 | 0.1363 |

| 28 | 0.3759 | 0.0148 | 0.1110 |

| 29 | 0.3454 | 0.0136 | 0.0937 |

| 30 | 0.3150 | 0.0124 | 0.0779 |

| 31 | 0.2946 | 0.0116 | 0.0682 |

| 32 | 0.2743 | 0.0108 | 0.0591 |

| 33 | 0.2540 | 0.0100 | 0.0507 |

| 34 | 0.2337 | 0.0092 | 0.0429 |

| 35 | 0.2134 | 0.0084 | 0.0358 |

| 36 | 0.1930 | 0.0076 | 0.0293 |

| 37 | 0.1727 | 0.0068 | 0.0234 |

| 38 | 0.1524 | 0.0060 | 0.0182 |

| 39 | 0.1321 | 0.0052 | 0.0137 |

| 40 | 0.1219 | 0.0048 | 0.0117 |

| 41 | 0.1118 | 0.0044 | 0.0098 |

| 42 | 0.1016 | 0.0040 | 0.0081 |

| 43 | 0.0914 | 0.0036 | 0.0066 |

| 44 | 0.0813 | 0.0032 | 0.0052 |

| 45 | 0.0711 | 0.0028 | 0.0040 |

| 46 | 0.0610 | 0.0024 | 0.0029 |

| 47 | 0.0508 | 0.0020 | 0.0020 |

| 48 | 0.0406 | 0.0016 | 0.0013 |

| 49 | 0.0305 | 0.0012 | 0.0007 |

| 50 | 0.0254 | 0.0010 | 0.0005 |

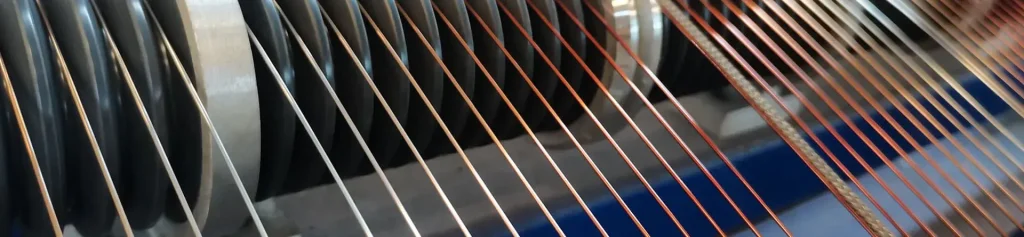

Key Considerations for Magnet Wire

When dealing with magnet wire (enameled wire), note the following:

- Bare Conductor Diameter: The values in the table refer to the bare copper conductor diameter only, not the overall diameter.

- Overall Diameter: The overall diameter (including the enamel/insulation) will be slightly larger. This increase depends on the insulation grade (Grade 1 / Single Build, Grade 2 / Double Build, or Grade 3 / Triple Build) chosen by the manufacturer, which affects coil design and winding requirements.

- SWG vs. AWG: SWG is typically used in older specifications or in regions outside of North America. Be careful not to confuse it with AWG. For example, 42 SWG (≈0.102 mm) is a much thinner wire than 42 AWG (≈0.063 mm). Always confirm the standard being used.