China Top-grade Eanmeled Wire Manufacturer

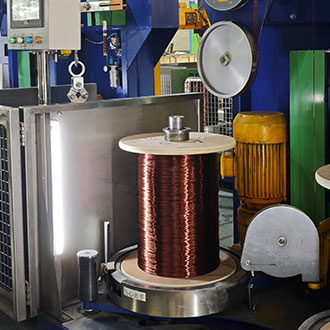

Zhengzhou LP Industry CO.LTD has the advanced enameled wire machine and Varnishing machine, also has the professional experts, which can be used to manufacture the awg and swg enameled wire. Materials has aluminum conductor, copper conductor and exporting Varnish producing the high quanlity common and special enameled wire used for transformer, motor, generator, car, aerospace and other industries.

Magnet wire Types

LP Industry is a wire supplier and exporter in China, prodives magnet wires and copper / aluminum foils, etc.Read moreCertificates

Our facility holds ISO 9001, ISO 14001, ISO45001and UL certifications, ensuring the highest standards in quality management.Read moreWire Uses

Magnet wire is used to create coils for transferring electrical energy in motors, transformers, inductors, and other electromagnetic devices.Read more

Zhengzhou LP Industry CO.,LTD

China Magnet Wire Exporter

Magnet Wire Manufacturing Process

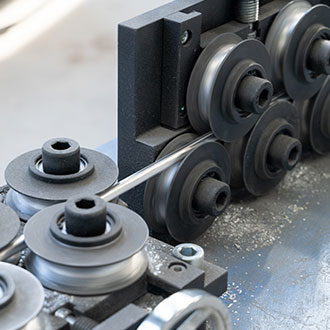

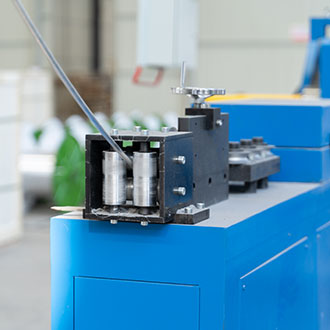

Integrating the art: extruding -- drawing --enameling and spooling

Trust and Choose LP Industry

Since the start it has been specializing in the R&D and production of magnet winding wires, being one of the 8 designated magnet wire suppliers for domestic transformer industry, which is certified by China Machinery Industry Federation and the State Grid,and particpating in the national magnet wire standards making. LP Industry takes the 3C Electrolytic copper panel and aluminum rod of high quality from Jiangxi, Chile and China Aluminum Corporation as the raw material, integrating the art: smelting –rolling –extruding — drawing –enameling and spooling in strict control to keep the quality of magnet wire stable and consistent. The company insists on the value “Quality Comes First”, and performs inspection on raw material, semi-finished products and finished products in 100%. Before shipment, we will carry out sampling inspection again and build traceable quality record. Taking the advantage of perfect quality and complete sales channel, LP Industry has established long-term partnership with famous brands all over the world such as ABB, Siemens, the State Grid and TBEA etc., ranking top in the industry all the time.

Global Collaboration, Trusted Quality

With high quality and a strong sales network, LP Industry has built long-term partnerships with global brands like ABB, Siemens, State Grid, and TBEA, maintaining a top industry position.